Best Practices for Using Forklift Truck Safety Signs in Industrial Park

Best Practices for Using Forklift Truck Safety Signs in Industrial Park

Blog Article

Ideal Practices for Displaying Forklift Truck Security Check In Industrial and Stockroom Settings

The implementation of reliable forklift vehicle safety signage is critical in commercial and storage facility atmospheres, where the danger of accidents can dramatically influence both workers and procedures. What details approaches can companies take on to guarantee their security signs truly serves its function?

Significance of Safety Signs

The importance of safety signage in atmospheres where forklift trucks operate can not be overemphasized, as these indications play an important duty in protecting against accidents and ensuring the safety and security of personnel. Effective security signage acts as a crucial interaction device, communicating important information regarding potential hazards related to forklift procedures. This includes warnings concerning pedestrian zones, speed limits, and assigned forklift courses, which are crucial for keeping an arranged and risk-free workplace.

Correctly shown safety and security indicators can boost situational understanding amongst workers, reminding them of the threats associated with their environments. They offer clear instructions on secure practices, such as putting on proper personal safety equipment (PPE) and adhering to operational guidelines. Furthermore, security signage adds to conformity with governing demands, aiding organizations prevent charges and advertise a culture of safety and security - Forklift Truck Safety Signs.

Along with their preventive function, safety and security indicators foster a feeling of responsibility amongst workers. When workers know safety protocols and the potential repercussions of disregarding them, they are most likely to take aggressive steps to shield themselves and their associates. Spending in high-grade safety and security signs is important for any type of office where forklift vehicles are in procedure.

Key Presence Variables

Reliable presence is paramount in making certain the security of both forklift drivers and pedestrians in busy workplace. To accomplish this, a number of vital visibility elements must be thought about when developing and positioning security indications.

First, the dimension and font style of the message on the sign play an important role. Larger typefaces improve readability from a distance, allowing individuals to promptly comprehend the message. Furthermore, the usage of vibrant and clear typefaces can substantially enhance clarity under various lighting problems.

Efficient Positioning Approaches

Sign positioning dramatically affects their efficiency in connecting security messages within forklift operations. To optimize visibility and understanding, signs should be purposefully placed in areas where forklift task prevails. Trick locations consist of crossways, dead spots, and near loading and unloading areas, where operators and pedestrians communicate regularly.

Height is one more vital variable; signs need to be positioned at eye level to ensure they are quickly seen by both forklift drivers and ground personnel. Furthermore, utilizing contrasting shades and clear graphics will certainly boost visibility, specifically in low-light problems or high-traffic areas.

Consider the flow of traffic when figuring out positioning. Signs should be positioned to lead operators safely and successfully via the workspace, decreasing the risk of mishaps. Normal assessments ought to be carried out to guarantee that signs continue to go to website be unhampered by devices or stock, as changing formats can reduce their performance.

Integrating responses from employees concerning sign positioning can likewise bring about renovations. Involving staff in this procedure fosters a culture of safety and understanding, eventually contributing to a more secure job environment. By implementing these effective placement techniques, companies can improve interaction and adherence to safety and security methods.

Conformity With Rules

Ensuring conformity with policies is essential for keeping a risk-free workplace in forklift operations. Regulative bodies such as the Occupational Safety and Health And Wellness Administration (OSHA) and the American National Criteria Institute (ANSI) develop standards that determine the appropriate use of safety indications. Adherence to these policies not just promotes safety and security however also minimizes the danger of fines and lawful liabilities.

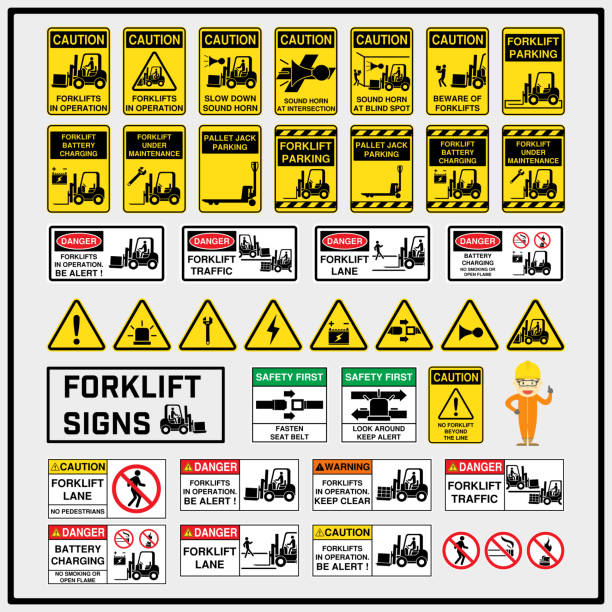

Forklift safety and security signs have to be plainly visible, readable, and strategically put according to regulative requirements. These signs ought to utilize standardized symbols and shade codes to convey crucial information successfully. Yellow suggests care, while red signals risk, making certain that staff members can swiftly interpret the signs in high-stress scenarios.

Organizations must carry out regular audits to validate that all safety signs fulfills existing legal criteria. Keeping up with changes in laws is also crucial, as non-compliance can result in considerable operational interruptions. By making sure that forklift safety indications comply with mandated guidelines, business cultivate a society of safety and security recognition amongst employees, thus boosting general work environment safety and security and performance. This commitment to compliance is an important facet of a reliable safety and security monitoring program.

Routine Maintenance and Updates

Preserving and upgrading forklift security indications is crucial for making certain his comment is here that they stay reliable and appropriate in the office. Normal inspections must be performed to evaluate the problem of safety and security indicators, as exposure to harsh industrial environments can bring about fading, damages, or obsolescence. Indications that are no more understandable or which contain out-of-date info can significantly weaken safety procedures.

It is vital to develop a regular maintenance schedule that consists of checking the exposure and clearness of all security signs. Any kind of signs that are put on, harmed, or misaligned need to be immediately changed or rearranged to maintain their performance. Furthermore, as regulations and security criteria advance, it is essential to upgrade signs to reflect existing practices and compliance needs.

Involving employees in security training sessions can additionally enhance the significance of maintaining and upgrading safety and security signs. This not just guarantees that every person article source is mindful of the indications' meanings however additionally promotes a culture of security within the office. By focusing on routine upkeep and updates, organizations can develop a more secure setting and improve the overall efficiency of their forklift safety and security signage.

Final Thought

In final thought, the application of ideal techniques for showing forklift vehicle safety indicators is necessary for enhancing office safety and security in industrial and stockroom settings. By focusing on visibility, using efficient positioning approaches, ensuring conformity with regulations, and committing to normal maintenance, organizations can substantially reduce the threat of mishaps. Such measures not only interact dangers efficiently yet additionally promote a society of safety and security that profits all staff members involved in forklift procedures.

Report this page